Specs at a glance

-

Measuring range

0.004 to 30 mg/l

0.05 to 330 %SAT

0.1 to 700 hPa -

Process temperature

1 to 140 °C

(32 to 284 °F) -

Process pressure

0.02 to 13 bar abs

(0 to 190 psi)

Field of application

Memosens COS81E is the ideal optical oxygen sensor for hygienic applications. Its well-tuned measuring system prevents ageing of the optical spot and offers precise, long-term stable measurements for high product quality. Thanks to its approvals for hazardous and dust-explosive areas, COS81E is perfectly suited for inertization applications. With Memosens 2.0 digital technology, COS81E offers extended data storage providing the perfect basis for predictive maintenance and efficient operation.

Memosens COS81E measures oxygen in applications with high demands to sterility and hygiene such as:

Fermentation

Drinking water production

Inertization

With its international explosion protection approvals, such as ATEX and IECEx, the Memosens COS81E oxygen sensor is suitable for hazardous area use.

Benefits

Memosens COS81E is designed according to EHEDG and ASME BPE. It avoids cross-contamination and is fully compliant to USP class VI and FDA as well as all GMP and GLP requirements.

High process up-time: Precalibrate the sensor in your lab and then swap it into your process with plug & play. It does not need polarization time and is immediately ready to measure.

-

Reliable measurement: A built-in reference LED compensates the ageing of the measuring LED. This ensures precise measured values even after CIP/SIP and autoclaving.

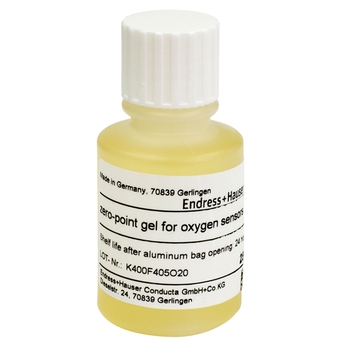

Reduce your maintenance effort: Memosens COS81E does not have a difficult-to-handle electrolyte or sensitive membrane. Just exchange the sensor cap, perform a calibration and you are done.

The sensor can be used in process applications as well as benchtop fermenters. Providing you with 100% measuring consistency from the first lab trials to the final scaled-up process and your process lab.

Perfectly suited for inertization processes thanks to its approvals for hazardous and dust-explosive areas.

IIoT ready: Memosens 2.0 offers extended storage of calibration and process data, enabling better trend identification and providing a future-proof basis for predictive maintenance and enhanced IIoT services.

Videos

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Predecessor

-

-

Technical Information (TI)

Memosens COS81E

English version - 04/2021

Hygienic optical oxygen sensor with maximum measurement stability over multiple sterilization cycles

EN 13/04/2021Language:

English

Version:

13/04/2021

File size:

1.6 MB

File name:

TI01558CEN_0120.pdf

-

-

-

Operating Instruction (BA)

Memosens COS81E

English version - 04/2021

Hygienic, optical sensor with Memosens 2.0 technology for the measurement of oxygen

EN 13/04/202102/10/2020Language:

English

Version:

13/04/2021

File size:

1.9 MB

File name:

BA02066CEN_0221.pdf

-

-

-

Technical Information (TI)

Memosens COS81E

Hygienic optical oxygen sensor with maximum measurement stability over

multiple sterilization cyclesEN 13/04/2021Language:

English

Version:

13/04/2021

File size:

1.6 MB

File name:

TI01558CEN_0120.pdf

-

-

-

Operating Instruction (BA)

Memosens COS81E

Hygienic, optical sensor with Memosens 2.0 technology for the

measurement of oxygenEN 13/04/202102/10/2020Language:

English

Version:

13/04/2021

File size:

1.9 MB

File name:

BA02066CEN_0221.pdf

-

-

-

Short Instruction (KA)

Memosens COS81E

Hygienic, optical sensor with Memosens 2.0 technology for the

measurement of oxygenEN 12/04/202102/10/2020Language:

English

Version:

12/04/2021

File size:

665 KB

File name:

KA01484CEN_0221.pdf

-

-

-

Installation Instructions (EA)

EA Kit COV81

For the maintenance of COS81D/E sensors

EN 02/10/202414/12/2022Language:

English

Version:

02/10/2024

File size:

757.4 KB

File name:

EA01460CEN_0224-00.pdf

-

-

-

Ex Safety Instruction (XA)

Memosens COS81E

Supplement to BA02066C

Safety instructions for electrical apparatus in explosion-hazardous

areasEN 05/07/2021Language:

English

Version:

05/07/2021

File size:

504.6 KB

File name:

XA02475CEN_0121.pdf

-

-

-

Ex Safety Instruction (XA)

Memosens COS81E

Supplement to BA02066C

Safety instructions for electrical apparatus in explosion-hazardous

areasEN 05/07/2021Language:

English

Version:

05/07/2021

File size:

591.3 KB

File name:

XA02476CEN_0121.pdf

-

-

-

Ex Safety Instruction (XA)

Memosens COS81E

UK Ex II 1G Ex ia op is IIC T6… T3 Ga

UK Ex II 1D Ex ia op is IIIC T90°C… T200°C Da

Safety instructions for electrical apparatus in explosion-hazardous

areasLanguage:

English

Version:

11/03/2022

File size:

419 KB

File name:

XA02842CEN_0122-00.pdf

-

-

-

Ex Safety Instruction (XA)

Memosens COS81E

KOR Ex ia op is IIC T6… T3 Ga

KOR Ex ia op is IIIC T90°C… T200°C Da

Safety instructions for electrical apparatus in explosion-hazardous

areasEN 18/03/2022Language:

English

Version:

18/03/2022

File size:

418.5 KB

File name:

XA02838CEN_0121-00.pdf

-

-

-

Ex Safety Instruction (XA)

Memosens COS81E

Supplement to BA02066C

Safety instructions for electrical apparatus in explosion-hazardous

areasEN 05/07/202115/10/2020Language:

English

Version:

05/07/2021

File size:

1.3 MB

File name:

XA02238CEN_0221.pdf

-

-

-

Ex Safety Instruction (XA)

Memosens COS81E

IS Class I Div 1 Groups A, B, C, D

Ex ia op is IIC T6 Ga

Class I Zone 0 AEx ia op is IIC T6 Ga

IS Class II Division 1 Groups E, F, G

Ex ia op is IIIC T90 °C Da

Zone 20 AEx ia op is IIIC T90 °C Da

Safety instructions for electrical apparatus in explosion-hazardous

areasEN 18/02/2022Language:

English

Version:

18/02/2022

File size:

498.7 KB

File name:

XA03098CEN_0122-00.pdf

-