Oil refinery optimization to meet modern market and regulatory demands poses significant challenges for today’s oil industry. Environmental standards render new projects more costly and complex. All operations must reduce air pollution emissions (NOx), meaning costly upgrades to existing installations. Low sulfur fuel demand is placing a premium on the hydrogen necessary in its production. Competitive pressures demand high performance with maximum safety and production flexibility.

Key facts

50%

of all refinery streams in the USA now pass through hydrotreaters for conversion, finishing, and pretreatment purposes. Hydrodesulfurization is the largest application of catalytic technology in terms of the volume of material processed. (Source: Topsøe H., Clausen B.S., Massoth F.E. (1996) Hydrotreating Catalysis. In: Anderson J.R., Boudart M. (eds) Catalysis. Catalysis-Science and Technology, vol 11. Springer, Berlin, Heidelberg)

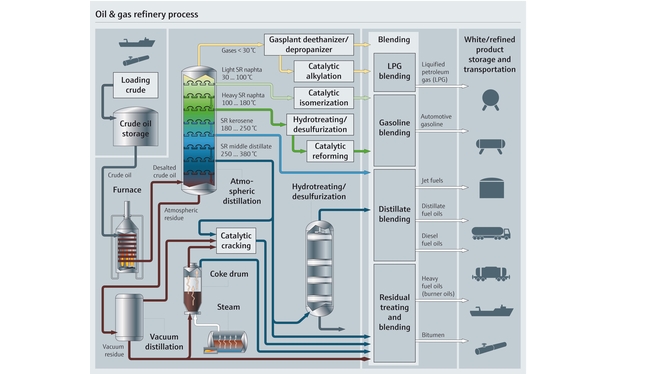

Zoom in refinery operation processes and applications

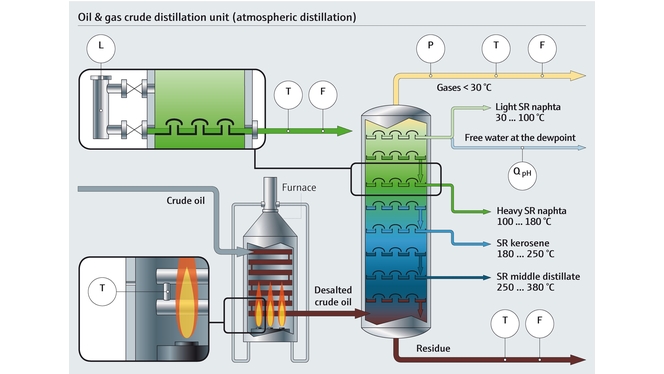

Measurement of crude distillation columns

Accurate and reliable measurement of crude distillation columns is critical for yield accounting, attaining production targets, planning and scheduling. The feed rate must be maximized, whilst ensuring that the mixture of crude types meets environmental specifications. Moreover, errors in measurements can lead to costly shutdowns or off spec products.

Our expertise in the field

Endress+Hauser engineers help design and select the right devices for your specific critical measuring points.

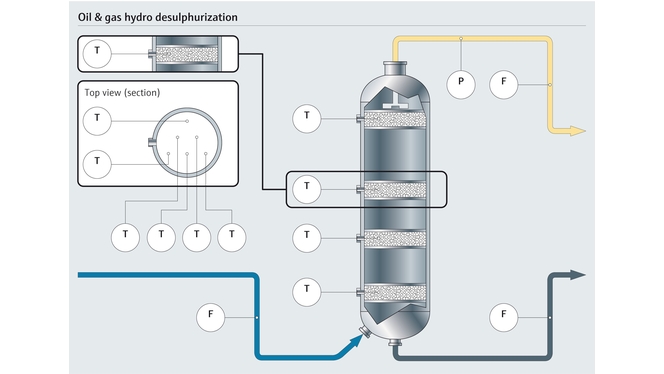

Reliable desulfurization

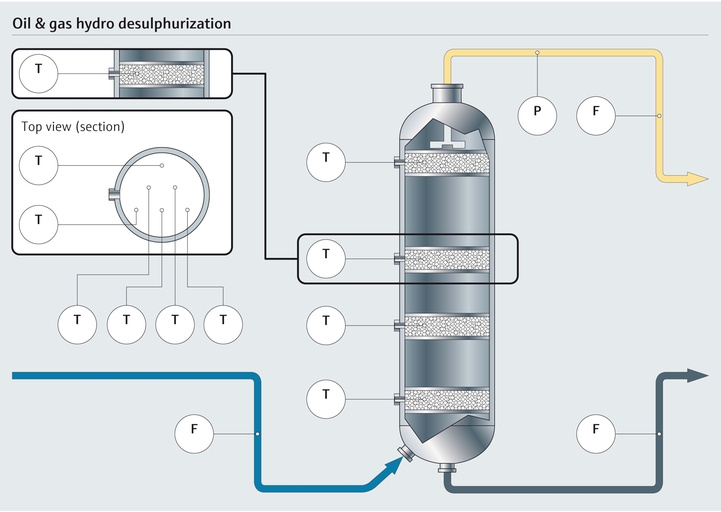

Ever stricter environmental regulations require significant reductions in the sulfur content of oil products, and such reductions can only be achieved through catalytic desulfurization in a hydrofiner. A key challenge for plant operators is to prevent channeling and hotspots within the hydrofiner for reliable desulfurization.

Our expertise in the field

Proven in use in many applications around the world, the Endress+Hauser multipoint temperature assembly MultiSens Flex contains multiple temperature sensors mounted in an individual nozzle. Your vessel requires only a minimal number of nozzles and openings to provide sufficient temperature measuring points for 3D monitoring and controlled, reliable desulfurization.

- Avoid unplanned shutdowns using Thermocouples that can be retracted and changed during vessel operation, if needed

- Prevent channeling and hotspots in the hydrofiner

- Increase efficiency, reliability and safety

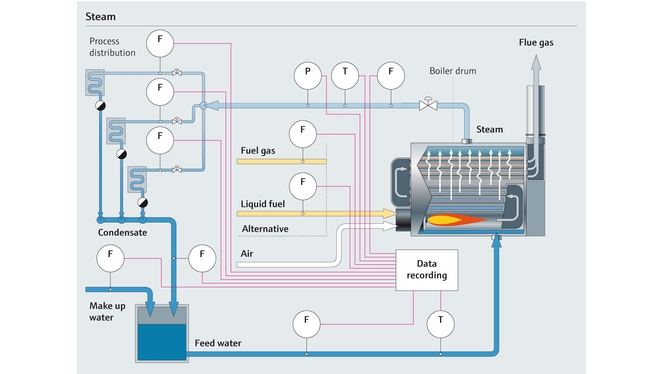

Steam boiler efficiency monitoring

The investment cost for a typical steam boiler can be considerable, and yet the very same boiler can consume as much as five times its initial capital cost in annual fuel consumption alone. Marginal gains in steam boiler fuel efficiency can therefore bring significant gains in overall oil refinery financial performance.

Our expertise in the field

Endress+Hauser smart scale energy solutions for steam systems enable optimal steam boiler monitoring to unlock fuel efficiencies.

- Gain visibility on fuel and steam consumption

- Identify, qualify and allocate losses in the system

- Optimize boiler performance

Benefits

As a refinery operator, you are under ever-increasing pressure to minimize costs, safety risks, downtime, and emissions while maximizing performance. Therefore you need a reliable partner that is here for the long haul. Our experienced team of engineers can help design and select the right devices for all of your critical measuring points to optimize your oil refinery process, while drastically eliminating the human risk factor.

Key facts

50%

total cost of ownerships savings offered by the electronic dP.

Key facts

Up to 50

measuring points per process connection can be freely directed in the fixed-bed reactor. As a result, you are aware of the real process optimization potential and you are able to predict catalyst life times.

Key facts

5 to 15%

estimated savings generated from remote energy management solutions

How we can help

Featuring highly accurate and reliable measuring devices, and cutting-edge automation solutions, the Endress+Hauser portfolio enables new opportunities for enhanced control and operation of complex refinery processes, storage and loading/unloading facilities. Moreover, with cost and environmental pressures placing the emphasis more firmly on efficiency, reliability, and safety than ever before, such opportunities for oil refinery optimization have never been so compelling.

- Drive plant efficiencies with maximum production availability

- Enhance production performance, whilst sustaining health, safety and security compliance

- Ensure alignment to the latest environmental standards