Monitoring Emulsion Polymerization Reactions

Process optimization via reaction endpoint detection and control of kinetics

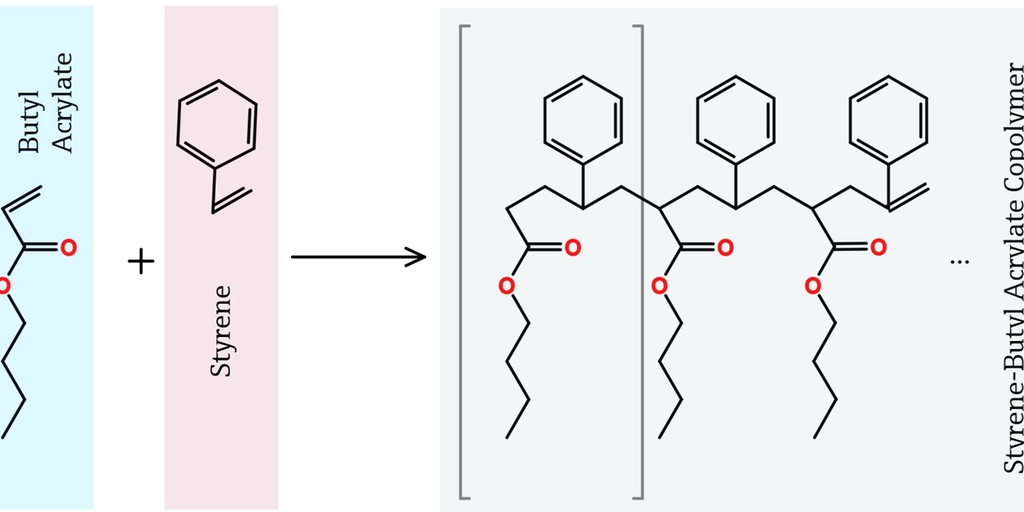

Emulsion polymerization is an important process for the production of a wide range of polymeric materials, including paints, adhesives and synthetic rubbers. The reaction is performed within an aqueous environment where the monomer species is maintained within a single phase with a suitable surfactant or emulsifier. The polymerization proceeds as a classical double bond addition reaction, initiated via a free-radical mechanism.

The chemical reaction of styrene-butyl acrylate emulsion polymerization.

The results

-

Measurement of specific double bonds

-

No interference with the aqueous matrix

-

Possibility to monitor reaction from outside, through the reactor walls

The challenge

It is important to be able to monitor the rate of consumption of the monomer species or the relative rates of consumption of the comonomers, when more than one monomer is used. This is necessary to ensure that the desired rate of formation of the product occurs. Also, if more than one monomer is involved, that the relative rates of reaction are consistent with the formation of the desired product. Another issue is residual monomer, as detected by the presence of unreacted double bonds.

Our solution

Raman Spectroscopy is well suited for monitoring these reactions insofar as it is sensitive for the measurement of specific double bonds, and it does not suffer with interference from the aqueous matrix. Furthermore, in studies with glass reaction vessels it is possible to monitor the reaction from outside, through the reactor walls.